20HP JIERU 15KW/8bar Permanent magnet variable frequency screw Air Compressor for Special air compressor for food, medical and electronic industries【oil-free water-lubricated】

Original price was: ¥7,888.00.¥6,888.00Current price is: ¥6,888.00.

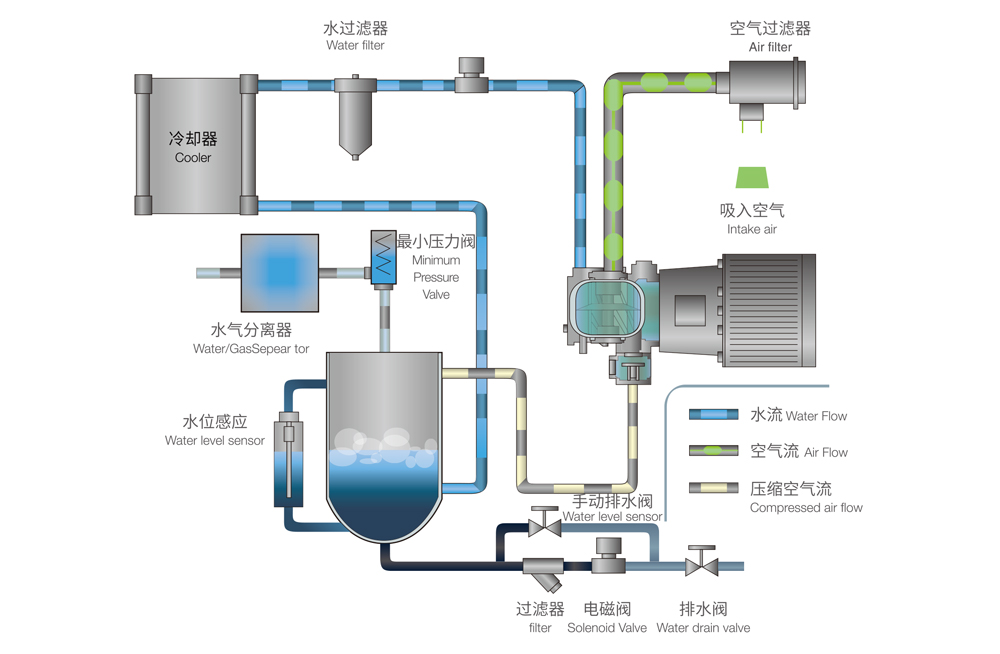

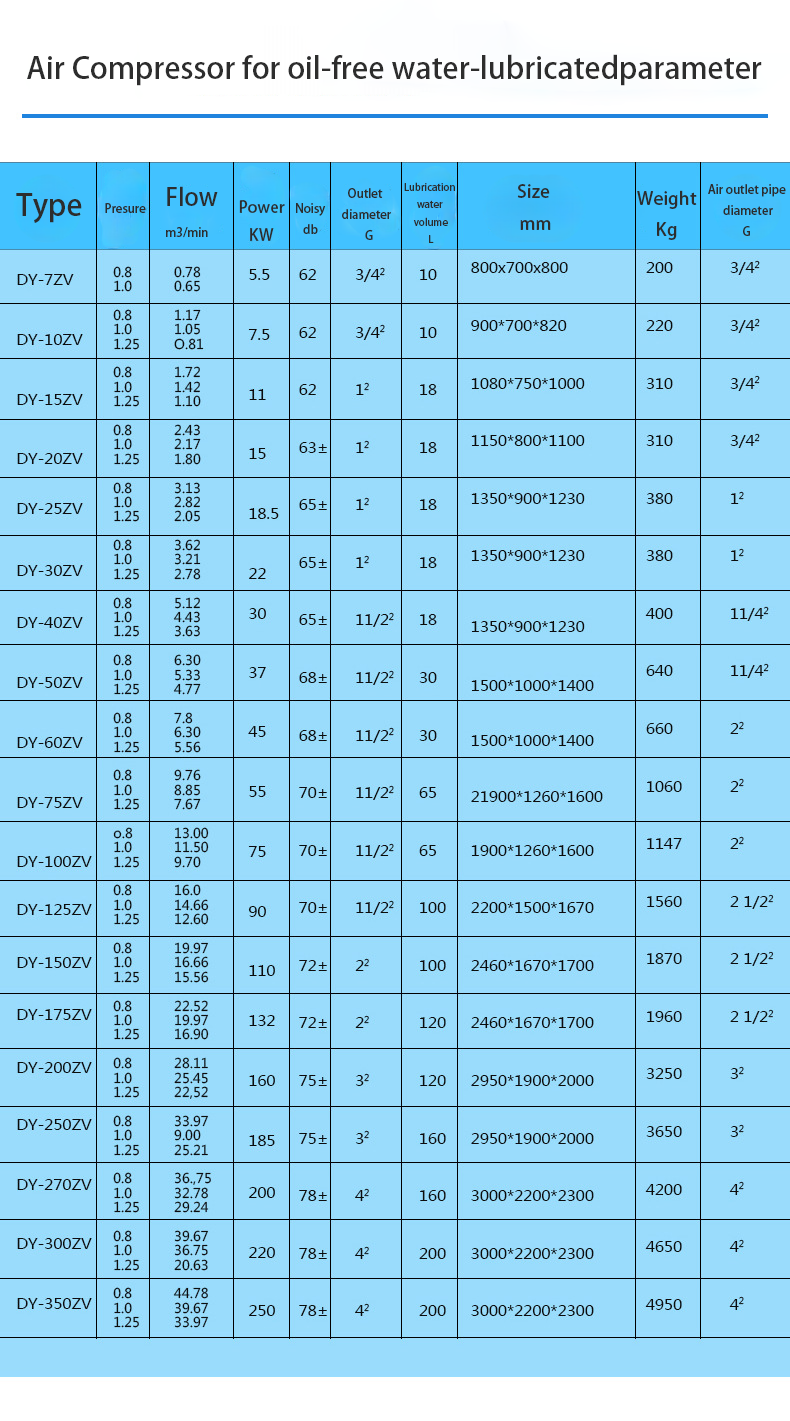

Air Compressor for Oil-free water-lubricated details

Place of Origin: Fujian, China

Brand Name: JIERU

Certification: ISO9001/ASME/ISO45001/ISO14001/GCCA/SAQM/CMIIT

Model Number:JR20A

Payment & Shipping Terms

Minimum Order Quantity: 1 set

Price: $6500.00/sets 1-1 sets

Packaging Details: Our packaging use fumigation wooden crate or carton.

Yield: 100 Set/Sets per Day

Air Compressor for Oil-free water-lubricated

: Guardians of clean air sources in the medical field advantages:

In the medical field, even the slightest contamination can lead to serious medical safety incidents. As the power source for many medical devices, the cleanliness and stability of compressed air directly impact the lives and health of patients. Oil-free, water-lubricated air compressors, with their zero oil pollution, high cleanliness, and strong stability, have become essential core equipment in the medical industry, playing an irreplaceable role in multiple critical scenarios.

I.Operating Room: “Sterile Power” in the Forbidden Zone

The operating room is one of the most demanding medical settings for cleanliness. Oil-free, water-lubricated air compressors provide pure power for various surgical equipment. During laparoscopic surgery, they drive the insufflator to inflate carbon dioxide into the patient’s abdominal cavity. Because the air source is oil-free and impurities-free, it reduces the risk of abdominal infection and ensures safe surgical procedures. For precision equipment such as high-frequency electrosurgical units and surgical robots, clean compressed air ensures the smooth operation of their pneumatic components, accurately executing the doctor’s instructions and reducing surgical errors. Furthermore, auxiliary equipment in operating rooms, such as pneumatic tourniquets and operating table lifting systems, also rely on the stable air supply provided by oil-free, water-lubricated air compressors to ensure smooth and efficient surgical procedures. After introducing this equipment into the operating room of a tertiary hospital, the postoperative infection rate dropped by 23%, and the failure rate of surgical equipment was significantly reduced.

II. Pharmaceutical Production: A “Safety Barrier” to Drug Quality

Pharmaceutical production must strictly adhere to GMP standards, and oil-free, water-lubricated air compressors play a critical role in this process. In the production of injectables, clean compressed air is required for everything from cleaning and drying ampoules to filling and sealing the drug solution. This air supply prevents contamination of the drug solution by oil mist from traditional oil-based air compressors, ensuring the sterility and purity of the injectable. In the production of tablets and capsules, equipment such as pneumatic tablet presses and capsule filling machines rely on oil-free, water-lubricated air compressors to power them. This not only ensures production efficiency but also prevents oil contamination from entering the raw materials, thus ensuring drug quality. In the biopharmaceutical industry, processes such as stirring and aerating fermentation tanks place even more stringent demands on the air source. The clean air delivered by oil-free, water-lubricated air compressors can be directly introduced into the fermentation system, providing a suitable environment for microbial growth and improving the success rate of biopharmaceutical production. A biopharmaceutical company using this equipment has consistently achieved a 100% pass rate for vaccines produced, successfully passing multiple international certifications.

III. Medical Device Cleaning and Disinfection: A Critical Link in Assurance of Sterility

Cleaning and disinfection of medical devices is crucial for preventing cross-infection, and oil-free, water-lubricated air compressors play a significant role in this process. In fully automatic cleaning and disinfection machines, compressed air is used to dry moisture from the surfaces of instruments. The clean air source provided by oil-free, water-lubricated air compressors prevents secondary contamination caused by residual moisture and prevents oil from adhering to instruments, which can affect disinfection effectiveness. For precision medical instruments such as endoscopes, high-pressure clean air is required for cleaning and drying their internal channels. Oil-free, water-lubricated air compressors provide precise and stable air pressure, ensuring thorough cleaning of every corner of the endoscope and reducing the risk of infection for patients. After adopting this equipment in a hospital’s disinfection supply center, the cleaning pass rate for medical devices increased to 99.8%, effectively ensuring clinical safety.

IV. Rehabilitation Therapy: A Reliable Aid for Patient Recovery

In the field of rehabilitation therapy, many rehabilitation devices rely on oil-free, water-lubricated air compressors for power. Pneumatic rehabilitation devices, such as intermittent pneumatic pressure therapy devices, massage the patient’s limbs through alternating inflation and deflation, promoting blood circulation and helping patients regain limb function. The stable air source provided by oil-free, water-lubricated air compressors ensures precise pressure control in the therapy devices, ensuring effective treatment while minimizing patient discomfort. Furthermore, some respiratory rehabilitation devices also require clean compressed air as an auxiliary. The zero-pollution properties of oil-free, water-lubricated air compressors ensure patient breathing safety and facilitate smooth recovery.

With their superior performance, oil-free, water-lubricated air compressors provide a solid cleanliness defense across all aspects of the medical field, safeguarding medical safety and patient health. With the continuous development of medical technology, the requirements for air source quality will become higher and higher. Oil-free water-lubricated air compressors will definitely play a more important role in the medical field and promote the development of the medical industry in a safer and more efficient direction.

Reviews

There are no reviews yet.