Water Cooling/Air Cooling 75HP Jieru Air Compressor for Energy Savings【double stage】

Product Details

Place of Origin: Fujian, China

Brand Name: JIERU

Certification: ISO9001/ASME/ISO45001/ISO14001/GCCA/SAQM/CMIIT

Model Number:JR-75PM-II

Payment & Shipping Terms

Minimum Order Quantity: 1 set

Price: $11,232.00/pieces 1-1 pieces

Packaging Details: Our packaging use fumigation wooden crate or carton.

Supply Ability: 100 Piece/Pieces per Day

Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction Works , Energy & Mining, Food & Beverage Shops, Advertising C | Showroom Location: | None |

Condition: | New, New | Type: | Screw |

Configuration: | Stationary | Power Source: | AC POWER |

Lubrication Style: | Lubricated | Mute: | Yes |

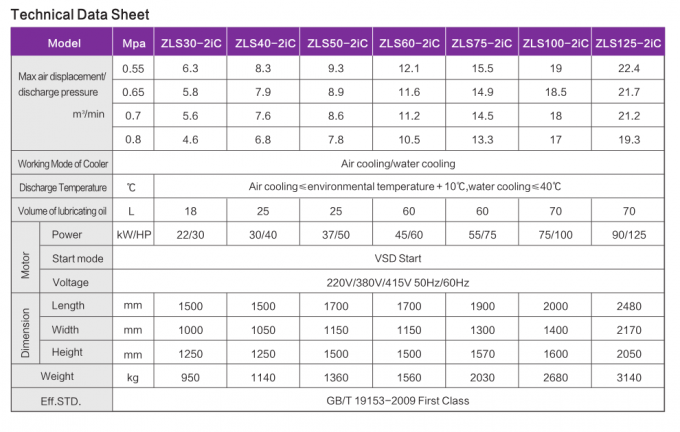

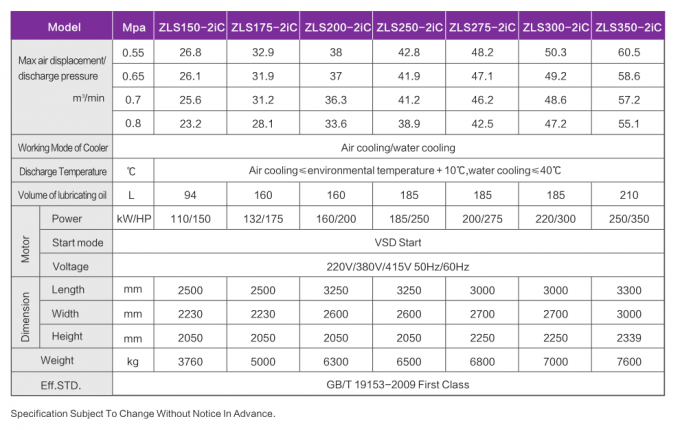

Voltage: | 415V/380V/220V/60HZ/50HZ | Dimension(L*W*H): | 1900*1300*1570 |

Weight: | 2030KG | Warranty: | 1 Year |

Working Pressure: | 8 Bar | Air Capacity: | 13.3 M3/min |

Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

Marketing Type: | Ordinary Product | Warranty Of Core Components: | 1 Year |

Core Components: | PLC, Pressure Vessel, Engine, Gear, Motor, Pump, Bearing, Gearbox | Gas Type: | Air |

Product Name: | Permanent Magnet Screw Air Compressor | Working Mode Of Cooler: | Air Cooling/Water Cooling |

Max Air Displacement: | 13.3 M3/min | After Warranty Service: | Online Support |

Local Service Location: | France, Viet Nam, Philippines, Brazil, Indonesia, Mexico, Thailand, Malaysia, Australia, Bangladesh, South Africa | After-sales Service Provided: | Online Support |

Port: | XIAMEN PORT |

Two independent electronic motors straightly drive the air end to work, the compressor obtains a relative speed consequently to reduce the leakage of pressure air, so it can output more pressure air, and be able to flexibly adjust the pressure, also it is easy to maintain and can keep long turn, therefore the performance in two stages is better than one stage.

updated, including 7-inch touch screen, special cooling spray and motor, director drive design. Moreover, we use all new technologies like communication system, dedicated fully intelligent driving algorithms.

1.JIERU intelligent drive as well as achieve without the gear wheel transmission.

2.JIERU Mechanical systems

● Combined with advanced rotor sealing and fluid dynamics technology, as well as the rotor line type, the rotor has high thermal insulation efficiency at all levels, so that each air end can achieve better performance;

● Using bearings with larger bearing capacity, the installation and preload calculation of the bearing are accurate, which improves reliability and prolongs the service life of the bearing;

● The main machine shell adopts a unique shape and position tolerance evaluation system and high-precision CNC machining technology to strictly control the internal clearance of the main machine, so that the main machine can maintain high reliability while having efficiency;

● The main engine adopts two-stage compression and inter-stage cooling, which has higher comprehensive insulation efficiency and achieves the purpose of energy saving.

● Compared with single-stage compressors, two-stage compressors can save up to 10%-25%

3.JIERU Powertrain

● The drive motor is directly connected to the secondary compression host without coupling, and the transmission chain is maintenance-free, reducing energy consumption by 1%;

● IP55 fully enclosed motor and host shell are integrated, which effectively prevents metal particles, dust, moisture and other pollutants from penetrating into the motor and main engine, making the compressor performance more stable.

● The motor bearing adopts reinforced cylindrical + ball bearing, which has higher strength and higher reliability;

● Transmission gears with processing accuracy up to aviation level 6, multiple heat treatments and related processing processes to ensure that all mechanical components have superior surface hardness, ultra-high wear resistance and yield strength;

● Independent oil supply system and precise oil filtration effectively ensure the stability and reliability of the entire gearbox under long-term full load operation.

Be the first to review “Water Cooling/Air Cooling 75HP Jieru Air Compressor for Energy Savings【double stage】” Cancel reply

Related products

Laser Cutting Air Compressor

Two-stage(higher efficiency energy saving)

Reviews

There are no reviews yet.